- Laboratory Analyzers

- OptiMVD Mini Viscometer and Density Analyzer

- 70Xi Series Pour, Cloud and Freeze Point Lab Analyzer

- 70Xi Series Cloud, Pour and Freeze Point Single Shot Analyzer

- 70Xi Series Cloud, Pour and Freeze Point Autosampler System

- JFA-70Xi Jet Fuel Freeze Point, Viscosity and Density Analyzer

- DFA-70Xi Diesel Fuel Cloud & Pour Point, Viscosity and Density Analyzer

- WAT-70Xi Wax Appearance Temperature Crude Oil Analyzer

- Service & Support

- Other Applications

- About Us

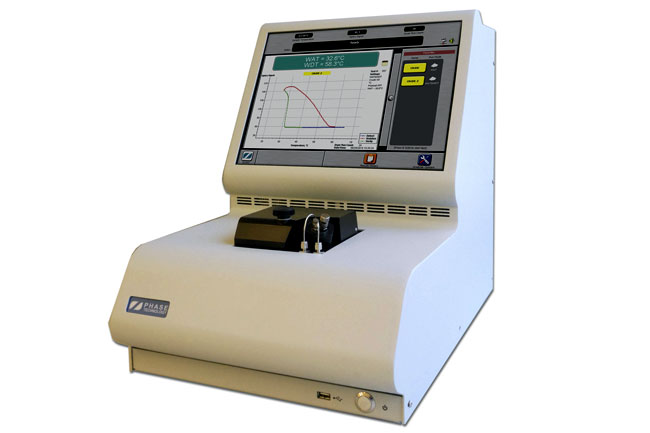

WAT-70Xi WAX APPEARANCE TEMPERATURE (WAT) LAB ANALYZER

With a long, notable history as the world leader in developing test methods for cold flow properties detection, Phase Technology has extended its capability to include a critical measurement for crude oil: Wax Appearance Temperature (WAT).

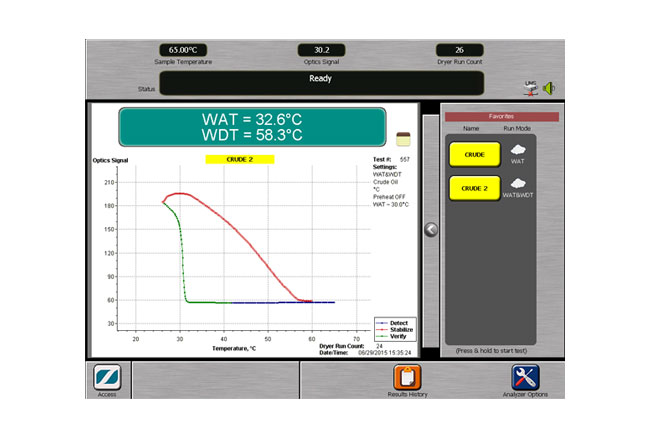

Also known as cloud point, wax appearance temperature is the temperature at which a crude oil sample first precipitates solid wax as it is being cooled under prescribed test conditions.

Similarly, Wax Disappearance Temperature (WDT) is the temperature at which the last wax solids are melted into liquid during a warming cycle.

Until now, trying to determine crude oil WAT or cloud point was an imprecise, tedious, and subjective process. Various manual methods have been tried, but all are difficult and time-consuming, yielding results with unacceptably wide error margins.

Phase Technology’s new WAT-70Xi analyzer revolutionizes the upstream and midstream oil industries with the world’s first and only totally automatic process to measure WAT and WDT of crudes. Following ASTM D8420 method, our proprietary optical light scattering technique detects phase changes with extreme sensitivity and accuracy.

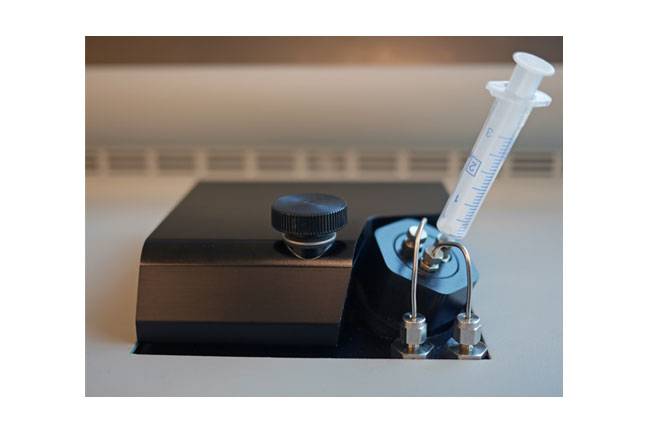

This important scientific break-through means that even the darkest, most opaque samples can now be easily tested, with 1.0° C precision. The Phase Technology WAT-70Xi offers a considerable efficiency advantage—just load the sample, and the analyzer does the rest, with tests completed in just 20-40 minutes. There’s no time-consuming manual set-up needed, and cleaning is done automatically after each test.

Read our White Paper to learn more about the importance of WAT and how it is detected.

Benefits

- Detection of both WAT and WDT – Two critical tests for understanding crude oil behavior; also determines rate of wax deposition & melting

- Super fast speed! – Test results in just 20-40 minutes, compared to average test times of several hours for other methods.

- Tests opaque samples – Enhanced optical configuration “sees” through dark samples Eliminates chance of cross contamination and other human errors

- Self cleaning – Automatic solvent flush after each test run

- No manual set-up – Simply inject sample directly into analyzer and begin test run

- Superior precision – Repeatability of 1.0° C

- Greater sensitivity – Controlled, automatic test method ensures no subjectivity in reported results.

Features

- Complete phase diagram (loop) clearly illustrates WAT, relative amount of wax formation and WDT.Easy-to-use interface; intuitive and simple to understand

- Full-color, touch-sensitive, 15” high resolution screen

- One-touch preset Favorites

- USB and Ethernet connectivity

- Import and store any user documents (.doc, .pdf, .ppt and .pps) for customized operating procedures (SOP) or training

- Customizable reporting – test history, plot data and self-diagnostics can be displayed on-screen, printed, or transferred to computer for statistical analysis, presentations, email sharing, archival storage

Applications

Wax appearance temperature (WAT) and wax disappearance temperature (WDT) can help predict the occurrence of wax deposition in crude oils, and are therefore useful for upstream and midstream petroleum companies.

In oilfield applications, WAT or WDT can assist in determining optimum levels of wax crystal modifiers and/or wax deposition inhibitors. WAT is also an indicator of potential crude incompatibility and a monitor of evolving crude quality. Crude oils from the same region may have quite different characteristics, with disparate rates of wax deposition and dissolution. Changes of location, extraction depth, evolution of time, or even methods of production and blending can all be verified by WAT.

For transport of crude oil via pipeline, railway or tanker, as well as for oil storage, wax crystals may restrict flow or create a total blockage. WAT and WDT can help define acceptable operability limits and prevent the downtime and expense associated with cleaning. WAT is a useful tool for the accurate prediction of wax deposition in pipelines and storage vessels, resulting in great potential savings. The design and development of subseas and land pipeline systems and implementation of wax remediation options benefit from analysis of WAT data.

Read our White Paper to learn more about the importance of WAT and how it is detected.

Specifications

|

STANDARD TEST METHOD |

ASTM D8420 Standard Test Method for Wax Appearance Temperature and Wax Disappearance Temperature of Petroleum Products and Liquid Fuels |

|||

| STATED PRECISION | Repeatability | 1.0 ºC | ||

| SAMPLE TEMPERATURE RANGE | -30 ºC to 65 ºC | |||

| SYSTEM CLEANING | Automatic flush cycle; external solvent tank | |||

| TEST DURATION | 20 to 40 minutes | |||

| REQUIRED OPERATOR TIME | 15 seconds | |||

| SAMPLE SIZE | 3.0 mL | |||

| DETECTION METHOD | Diffusive Light Scattering (DLS) technology (over 25 patents) |

|||

| COOLING SYSTEM | Integrated Peltier device cooling system | |||

| DISPLAY | Full-color, touch-sensitive, 15” high resolution LCD touch screen | |||

| OUTPUTS |

(3) USB A ports for flash drive, label printer, barcode scanner keyboard, mouse (1) USB B port (3) RS-232 serial ports for optional accessories, LTB diagnostic software, external computer (1) dedicated Service port (1) 10/100Base-T Ethernet (RJ45) port for networking: LIMS, local area network (LAN) |

|||

| TEMPERATURE MEASUREMENT | ºC or ºF (user selectable) | |||

| ALERTS | Audible tone alerts (user selectable) | |||

| INTERNAL MEMORY | Storage up to 5000 test runs (minimum) | |||

| AMBIENT OPERATING ROOM TEMPERATURE | 10 to 30 °C (50 to 86 °F) Extremes not recommended |

|||

| DIMENSIONS (L X W X H) |

Unit |

21.5 x 13.25 x 17.5 inches 54.6 x 33.7 x 44.5 cm |

||

| Boxed | 29 x 23 x 19 inches

74 x 58 x 48 cm |

|||

| WEIGHT | Unit | 53

lbs 24 kg |

||

| Boxed | 62 lbs 28 kg |

|||

| UTILITY REQUIREMENTS | Electrical | 90 – 280 VAC, 47 – 63 Hz 350 watts |

||

| External cooler bath | NONE | |||

Photos

Brochure

Click here to download a brochure

Order Information

You can purchase Phase Technology products from our global network of authorized sales agents. To find an agent near you, please contact us.

Need a quote? Complete our contact form and we'll respond either by phone or email right away. Please be sure to check the “Request a Quote” box under “I am interested in,” or type in your specific request in the “Comments/Questions” box.

In a hurry? Call us directly at 604-241-9568 for immediate attention during business hours (8 am - 5 pm Pacific Standard Time). You can also leave a voice message and we’ll return your call.

Contact a Sales Representative about this product.

Send Inquiry

WAT-70Xi Crude Oil Analyzer [pdf]

Phase Technology White Paper - WAT of Crude Oil [pdf]